Manufacture of machinery for the dairy and food industry in Italy

Inox Arte has always been involved in the design and installation of machinery and equipment for the dairy industry, particularly dairy plants for the production of various types of stretched-curd cheeses, such as mozzarella.

Inox Arte's plants are safe, reliable, and effectively combine the benefits of industrial standardisation with the care and control of artisanal craftsmanship. The experience gained over the years has allowed Inox Arte to become a national leader in the field of stretched-curd cheese production.

New production line BURRATE

Composed of the tilting mixer MIRP, the shredder MPS 500, and the volumetric dosing machine.

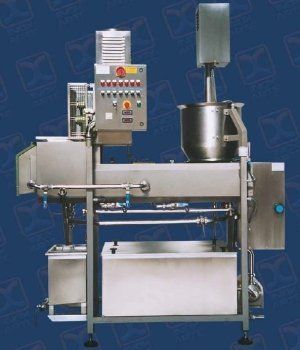

Spinning-forming machine FFC/2000 Uniblock

The continuous spinning and forming group model FFC/2000 Uniblock has been designed and built for the processing of dairy-derived pastes through the combined use in series of:

- A dough cutter machine, capable of slicing manually introduced curd blocks into the hopper and cut by four adjustable blades mounted on a disc;

- A spinning machine capable of mixing the curd from the cutter in the processing tank, continuously moistened by the introduction of hot water, and conveyed by two intersecting screws at variable speeds to the spinning section where two variable-speed plunging arms give the product the right spinning and moisture content for any type of processing;

- A forming machine designed to shape and maintain a consistent size of the product.

Spinning-forming machine FFC/500 Uniblock

Compact group: cutting, spinning, and forming.

Production up to 400 kg/h.

Suitable for the production of: mozzarella, bite-sized pieces, braids, and provolone.

Constructed in stainless steel AISI 304. All parts in contact with the product are coated with TEFLON DU-POINT, sintered at high temperatures.

The group consists of:

- Circular curd cutter, mounted on the machine, with self-flipping for washing operation.

- Curd cooking compartment, consisting of a double chamber for temperature maintenance and double counter-otating screws.

- Dough kneading compartment (spinning) equipped with a plunging arm system. The machine is equipped with a hot water preparer, with automatic operation that provides the necessary water for processing. Direct steam heating system, with silencers.

- Forming unit applied to the spinning dough compartment, forming a single body with it. Equipped with two counter-otating screws and a heated chamber with electric resistance, regulated by an electronic thermostat.

Spinning-forming machine FFD/150 discont.

Discontinuous spinning and forming group, designed for small businesses, with artisanal processes. Suitable for the production of mozzarella from 5 to 500 g, braids, small braids, scamorza, provolone. Constructed entirely in stainless steel AISI 304 and food-grade plastics.

Composed of:

- Adjustable blade curd cutter, mounted on the kneading compartment;

- Dough kneading compartment with plunging arm system with variable speed;

- Forming unit applied to the spinning and forming machine, forming a single body with it;

Continuous spinning-forming machine IA/95 v150

The spinning machine model IA/95 has been designed and built for the continuous production of stretched-curd cheese starting from the curd appropriately sliced by the curd cutter, then collected in the processing tank and conveyed by two intersecting screws to the spinning section.

To maintain a constant spinning water temperature, the machine has an insulated tank filled with appropriately heated water.

Forming machine IA/91

The forming machine model IA/91 is a machine designed for large dairy farms, ideal for the production of stretched-curd cheese products such as mozzarella, fiordilatte, provolone, braids, and knots. It can accommodate accessories such as moulds with weights from 2 to 600g and an extruder mould for braids and knots.

The machine can be fed with manually loaded dough or with tilting mixers directly into the former. The machine's inclination is set at the company.

Constructed entirely of stainless steel AISI/304, all parts in contact with the product are coated with non-stick material TEFLON DU POINT.

Forming machine IA/45 RP

The forming machine model IA/45 RP is a machine designed for medium-sized dairy farms, ideal for the production of stretched-curd cheese products such as mozzarella, fiordilatte, provolone, braids, and knots. It can accommodate accessories such as moulds with weights from 2 to 600g and an extruder mould for braids and knots.

The machine can be fed with manually loaded dough or with tilting mixers directly into the former. The inclination of the machine allows obtaining a soft product with a high moisture content.

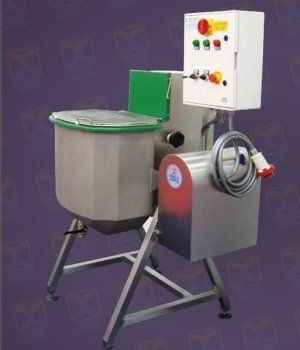

Mixer machine IA/12 R30C

The mixer machine model IA12/ R30C has been designed and built for the processing of dairy-derived pastes using two opposing rotating augers at variable speeds.

The dough is continuously humidified by the introduction of hot water until a soft and homogeneous paste is formed, essential for the production of mozzarella, scamorza, provolone, and caciocavallo.

Curdcutter machines IA/10 - IA/11 - IA/11p

The curd cutter machine Mod. IA/10 has been designed and built for the cutting of curd intended for the production of stretched-curd cheeses. The curd blocks are inserted into the cylindrical hopper divided into two sections and are cut by four adjustable blades to obtain slices of the desired thickness. To recover the cut product, it is necessary to place a collection bucket under the conveyor.

Request a quote

Automatic stretching machine TF 35

The stretching machine model TF/35 is a machine designed for the discontinuous production of stretched-curd cheese, starting from curds that have been appropriately chopped and introduced into the kneading compartment.

Where two plunging arms act, giving the product a homogeneous stretch, with the desired moisture content.

Melter FVA/40 – FRPA

The stretching-forming group model FVA40 - FRPA is designed for the stretching and forming of fresh or frozen dairy-derived pastes for the production of mozzarella, fiordilatte, provolone, braids, knots, etc., through the combined use in series of:

a stretching machine for stretching the curd introduced in blocks or sliced in the processing tank is continuously humidified by the joint injection of water and steam. The curd introduced into the compartment is processed by two intersecting screws at variable speeds with independent rotation directions from each other, advancing both forward or backward or in opposite directions, giving the product a stretch and the right level of moisture for any type of processing.

Hot water preparer PV/300

The hot water preparer model PV/300 is designed and built exclusively for the continuous production of hot water, at a variable temperature depending on your company's needs, up to a maximum operating temperature of 90°C.

Heating is carried out through the circulation of steam in a closed circuit, in the interspace formed by TRAPCOLD-type plates, through a steam flow regulation solenoid valve with a thermostat. All parts of the machine are made of stainless steel AISI/304, to meet the strictest food and hygiene regulations, guaranteed by the easy cleaning of the parts. Thermally insulated by a rock wool mattress, on the cylindrical part of the tank, and externally coated in finely satin or floretted stainless steel.

Ricotta production boiler

The ricotta production boiler is designed and built exclusively for the cooking of milk and whey for the production of cheeses and ricotta in general. They are insulating containers with a double heating section through superheated steam, equipped with a drainage system for the discharge of water produced by steam condensation. The heating of the food product is achieved by acting through one or both heating sections depending on the quantity introduced. It can also be used as a discontinuous pasteurizer and equipped with temperature control instrumentation.

The machine has been entirely constructed in stainless steel AISI/304 to meet the strictest food and hygiene regulations, guaranteed by the easy cleaning of the surfaces.

Multipurpose tanks on load-bearing structure

The multipurpose tanks, produced by Inox Arte, are designed and built for the processing of bovine and ovine/caprine milk intended for the transformation of curds for stretched-curd cheeses or cheeses in general.

Request a quote

They are constructed in stainless steel AISI/304 in a vertical cylindrical shape, mounted on a load-bearing structure equipped with adjustable feet for levelling. Access ladder with protective railing.